Production Targets: What They Are and Why You Should Use Them

Timely, data-driven decision making is a key to successful heavy construction operations, and contractors can’t make good decisions without gauging actual performance in the field against the expectations established in the estimate. That comparison on a daily basis provides supervisors with the means to address job issues and make corrections days or even weeks before reports can be generated through their company’s accounting/job cost systems.

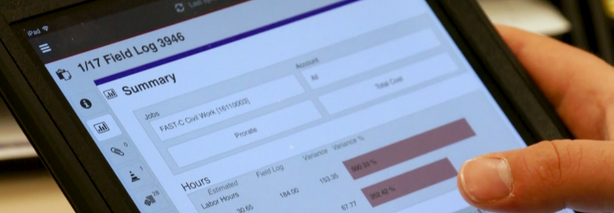

Capturing accurate labor hours and production units daily is one part of the equation. That data, however, is just data without a tool to easily compare it to the estimate. That’s where production targets come into play and can deliver a significant advantage over setting expectations based simply on daily averages.

Properly configured systems for field tracking and data capture provide precise, immediate feedback on performance and productivity. This data should be generated in the field, at the source, and there should be no need to wait for it to be returned and distributed from another system.

Add the ability to set daily performance targets, and this analytical feedback on performance can be even more dialed in and valuable. Managers can set targets that provide meaningful feedback on a daily basis and they can pinpoint expectations based on the conditions for that day, as opposed to the average production rate provided in an estimate.

Let’s look at an example…

For a 10,000-ton paving job estimated to take 10 days, the simple thing to do is to set up field logs to indicate an expectation of 1,000 tons of productivity per day for 10 days. In reality, the crew would not be expected to hit the same performance target every day due to any number of legitimate variables. The actual plan in the field may call for 500 tons daily over the first five days and then 1,500 tons daily for the next five days.

Using the estimated average production rate of 1,000 tons per day to gauge daily performance is a useful tool in summary, but it does not provide an accurate impression of job status on a specific day over the course of the project. After day four, for example, reporting would show only 2,000 tons completed versus a plan of 4,000 tons. That might raise a red flag that crews were 50% behind schedule. (This could also have obvious and major implications on the schedule for producing and delivering asphalt, but that’s a topic for another blog post.)

By setting variable production targets that are relative to actual conditions and expectations for each day, a much clearer indication of job status can be obtained at any given time.

There is another advantage to consider. Depending on culture and management, many companies do not want actual cost information shared among forepersons and field employees. Production targets provide a perfect opportunity to review productivity measures that ultimately indicate daily profitability without exposing estimate cost details.

Let’s face it, employees inherently want to know how they are performing compared to expectations. Managers also need that information in order to make the right decisions and adjustments. Daily production targets provide a more accurate and precise way to compare actual performance to estimated performance and to use that data to keep projects on schedule and on budget.

View this brief video to learn more about B2W Production Targets – A Better Way To Track Productivity.